Technical & Technology on Audio Test Blog

The discovery of SysCheck2

Julie works for a leading audio brand manufacturer in China and is preparing to set up and oversee a new production line. The line will produce high-end audio components that will need a full audio test for each product at the end of the line.

The most efficient way to ensure high-quality measurement data is regular calibration and frequent checks of the entire measurement chain. Calibration is time consuming all by itself, but on a production line, it frequently involves opening or disassembling test apparatus to reach the microphone. Calibrating devices that are incorporated in complex structures such as ear simulators or audio test boxes is even more time consuming because great care must be taken when dismounting and remounting the acoustic fixture. This not only adds an extra layer of time, but also costs as it should only be performed by a trained engineer to ensure proper calibration and avoid damage to the measurement station and equipment.

In order to streamline the production and reduce the down time, Julie has come up with a new setup, and equipped the production line with SysCheck2-enabled microphones. She then brought in a technician to perform an initial calibration of the measurement chain. As part of the initial measurement-chain calibration process, a SysCheck2 reference level is measured and saved together with the environmental parameters at the time of calibration. All of that information is acquired by the measurement analysis software with a single click.

Now, when an operator’s shift begins, and rather than recalibrating and checking the measurement chain, they validate the measurement chain by running a SysCheck2 verification with a single click. This enables the operator to verify that nothing changed in the measurement chain since the last calibration. Once the operator gets a Go/No Go answer from the software (taking less than 10 seconds (depending on the algorithm used)), they can start testing the devices. Every hour (or every time he takes a pause) they run a new SysCheck2 verification. This validates all the devices that were tested since the last SysCheck2 verification. This means that they can validate the entire production without having to rely on calling a specially trained person to periodically verify the measurement chain.

The result is that the line only needs to be stopped for calibration in the unfortunate event where the software returns a change in the SysCheck2 level; only then must the operator call a technician to fix the problem. And only the devices tested since the last verification need to be retested.

As a bonus, thanks to the environmental sensor present in the microphone, Julie can correlate the measurement data with temperature, humidity and static pressure and foresee changes in production tolerances due to environmental variations.

The system showed green all day, and confident in the validity of the system, the line functioned without unscheduled stops. With data processed, reports generated and numbers totaled, Julie headed home for the day—it was a good day.

How do you measure Loudspeaker Rub and Buzz

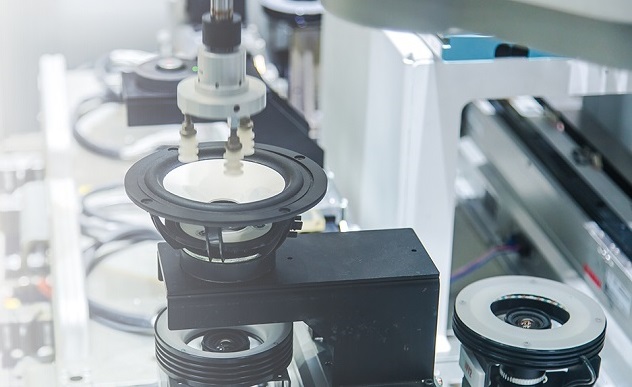

When designing acoustic products, the speaker driver itself needs to go through quality assurance testing then again once the driver is implemented into the final product. The dual testing ensures the product works properly on its own and the surrounding device the speaker is introduced into is not causing the speaker to become defective. Amongst the many tests quality assurance puts a product through, in an acoustic product like a loudspeaker, detecting Rub & Buzz is critical before the product is shipped to the end customer. In this application note, we introduce what Rub & Buzz is and define four Rub & Buzz detection results used on production lines.

Download our application note here...

What is the difference between acoustics and aeroacoustics?

The answer is…

Aeroacoustics is a subset of the field of acoustics. The end...

But before you go, it’s not quite so simple as it may seem, and it is much more interesting.

According to the Oxford English Dictionary, Acoustics is the branch of physics concerned with the properties of sound, and aeroacoustics is a subcategory. However, while aeroacoustics definitely falls under that umbrella, it also encompasses aerodynamics, which contributes to the conditions that cause the sound; and therefore, it gets a little complicated.

Noise in aeroacoustics involves both traditional aspects (like source path contributions, transmissivity, dampening, etc.) and aerodynamic contributions.

Aerodynamics is the study of how an object affects the medium (gasses, in this case) through which it moves or how the gasses or fluids move around the object. In day-to-day life for most, this is typically air.

And this is what makes aeroacoustics so interesting. It is the by-products of the aerodynamic forces themselves that make up much of the noise in aeroacoustics—in other words, it is the motion of the object through the medium itself that instigates the noise events in and around the object. For example, external air pressure fluctuation can cause a deflection in the surface material itself, turning it into a diaphragm, which if it’s thin enough, will generate noise. Or airflow across an edge creates vortices that can result in a whistling sound. This whistle can then be heard outside the structure and propagate inside—where the structure might dampen or amplify the sound, which involves the transmissivity of the materials. Or it could result in purely structure-borne sound to be heard in odd places around the structure. This noise could then be masked by other noise depending on the various source path contributions.

And the key to understanding how to mitigate or entirely remove that noise is understanding aerodynamics and how that disruption in the airflow can be reduced—for example, by altering the structure to remove an edge or directing the flow such that the turbulence occurs at a different point in the flow. This is complicated enough when only dealing with a motor vehicle or aircraft noise, but altering the design can have a great effect on the lift and drag aspects of aerodynamics.

It is true that aeroacoustics is “just” a subset of acoustics, but it is becoming more and more intertwined with aerodynamics. And with the continued move towards greener energy sources and electric vehicles the relationship only gets stronger. Aircraft and vehicles have more stringent noise requirements, and in the case of the much quieter electric cars, any aeroacoustic noise is more prominent due to the lack of the engine and transmission masking noise. And often, solving that problem aerodynamically will impact the drag coefficient, decrease drag and improve battery life.

So, sure. Aeroacoustics is a subset—but so much more.

If you want to know more about "Turbulence and Measuring in Boundary Layers", download our whitepaper.