-

Products

- AP Audio Analyzers

-

GRAS Sound & Vibration

- Measurement microphone sets

- Measurement microphone cartridges

- Preamplifiers for microphone cartridges

- Production line microphones

- Ear simulator kits

- Special microphones

- Head & Torso Simulators

- Artificial ears & mouth simulators

- Power modules

- Test fixtures

- Hemisphere kits

- Microphone Arrays

- Cables

- Accessories

- Calibration equipment

-

Echo T&M Audio Test Interfaces

- AIO-A1 Multi-channel Acoustic Test Interface

- AIO-A2 Multi-channel Acoustic Test Interface

- AIO-L1 Multi-channel Line-level Test Interface

- AIO-L2 Multi-channel Line-level Test Interface

- AIO-SA Multi-channel Acoustics Test Interface & Impedance

- AIO-AT Multi-channel Acoustic and Digital Test Interface

- AIO-LT Line-level & Digital Test Interface

- AIO-S1 2-Ch Acoustic Test Interface & 1-Ch Impedance

- AIO-S2 4-Ch Acoustic Test Interface & 2-Ch Impedance

- Acoustic Chamber

-

Turntable

- RF products

-

Transport Case SKB

- Applications

- Services

- Technical Library

- News

- About us

- Contact

Acoustic Applications for Electric Vehicles

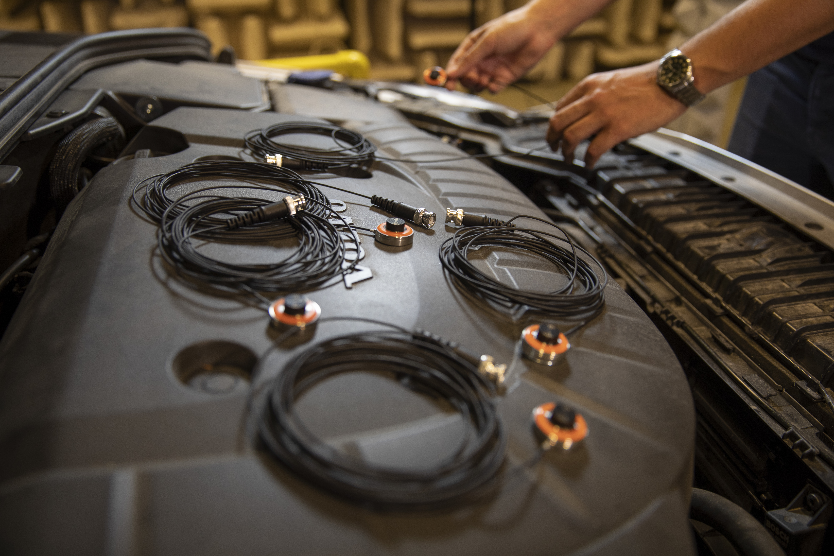

Measuring acoustic performance on an electric vehicle (EV) or hybrid-electric vehicle (HEV) platform introduces new challenges compared to typical internal combustion engine (ICE) platforms.

Most sounds from an EV platform are comparable to those in an ICE platform in level and frequency range, but they differ in content. Generally, existing measurement setups can be transferred to EV platforms and cover most of the basics.

With the introduction of EVs, however, new types of noise sources have been introduced, especially from the inverter, electric motor, battery charger and lightweight damping material.

There is no low-frequency engine noise in EVs to mask other noises, which is why new high-frequency tonal noises are much more distinct in EVs. At high speeds, the motor e.g. will cause a howling sound, which can be very disturbing to the driver.

The general increase in high-frequency content makes it difficult to do TPA/ENR types of measurements. Many sound sources have very limited energy already at 10 kHz which makes transfer path analysis from the engine bay more difficult.

In an environment with high frequency content, extra care therefore has to be taken in order to measure and map the distribution of content reliably.

Inverters

Inverters emit noise related to the switching frequencies and duty cycle. Switching frequency will typically be constant in frequency whereas duty cycle will change with load. Thus, the load will change at acceleration or regeneration.

Electric motor

There are many different solutions for electric motors for EV platforms. Typically, there will be a single large motor, but there can just as well be two or four depending on purpose, performance, etc.

Charging

Since charging the battery most likely will utilize the same power electronics as at regeneration – though at a more constant rate – this may generate an unpleasant whine from the power electronics and discourage passengers from staying in the car during charging.

Lightweight damping material

As OEMs are struggling to reduce the weight in EVs, the damping in different locations may be reduced with time.